- Home

- Corporate

- Our Manufacturing

- Baklava Machines

- Borek / Burek / Patty Machines

- Manti Ravioli Dumpling Machines

- Thick Dough Machines

- Triangular Phyllo Cutting Machines

- Horizontal Mixers

- Kebbah / Kibbeh Stuffed Meatball

- Lavash Lines

- Noodle Machines

- Shredder Machines

- Sambusa Dough Machines

- Pasteurization Machines

- Phyllo Line / Yufka Line Machines

- Pizza Dough / Pizza Base Machines

- Turkish Delight Machines

- HR

- Blog

- Contact

English

English

- Home

- Corporate

- Our Manufacturing

- Baklava Machines

- Borek / Burek / Patty Machines

- Manti Ravioli Dumpling Machines

- Thick Dough Machines

- Triangular Phyllo Cutting Machines

- Horizontal Mixers

- Kebbah / Kibbeh Stuffed Meatball

- Lavash Lines

- Noodle Machines

- Shredder Machines

- Sambusa Dough Machines

- Pasteurization Machines

- Phyllo Line / Yufka Line Machines

- Pizza Dough / Pizza Base Machines

- Turkish Delight Machines

- HR

- Blog

- Contact

English

English

- Lavash Lines

- Turkish Delight Machines

- Shredder Machines

- Horizontal Mixers

- Pasteurization Machines

- Noodle Machines

- Triangular Phyllo Cutting Machines

- Sambusa Dough Machines

- Pizza Dough / Pizza Base Machines

- Thick Dough Machines

- Phyllo Line / Yufka Line Machines

- Kebbah / Kibbeh / Icli Kofte / Stuffed Meatball

- Baklava Machines

- Borek / Burek / Patty Machines

- Manti Ravioli Dumpling Machines

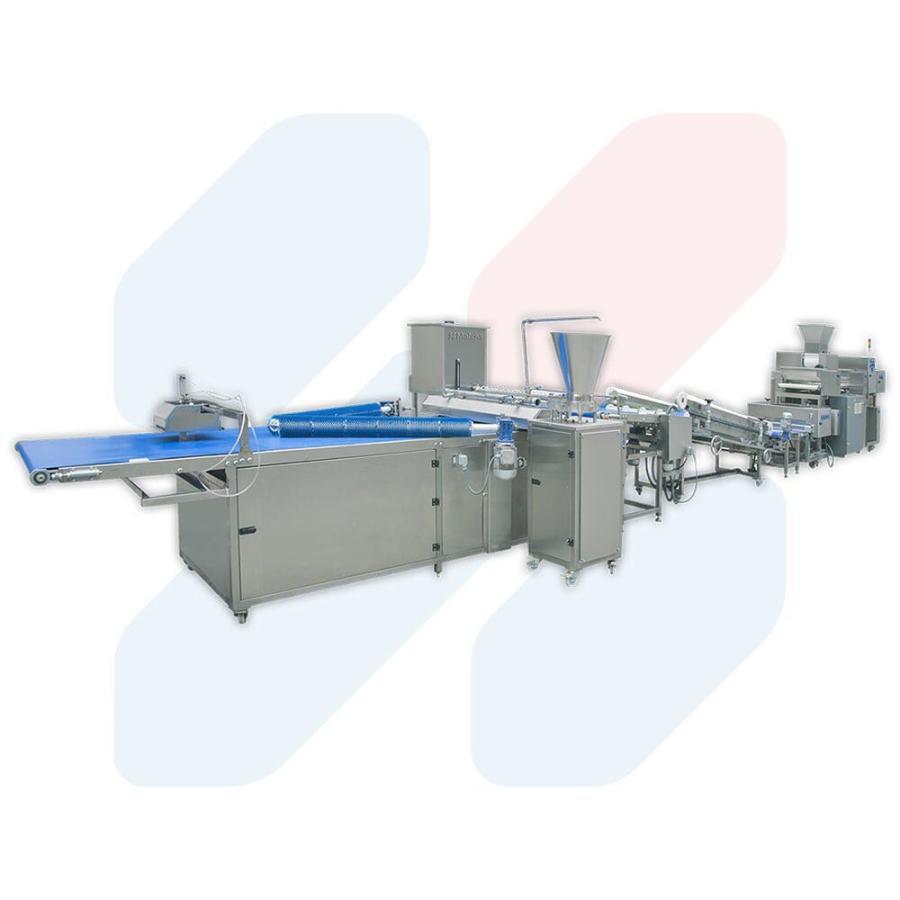

Borek / Burek / Patty Machines

Making a borek or Burek or Patty, which is one of the essential products both for breakfasts and treats, is a very demanding work. It is required that the dough is thinly rolled out and borek is arranged in several layers of dough, which doubles the taste of the borek, and all phyllo sheets should have equal thickness. Normally, at homes, a few trays of borek are made while for mass production, borek machines combined with advanced and innovative technology as well as labour accelerate this process.

In addition to making boreks in the desired form with Borek / Burek / Patty Machines, it is aimed to increase work efficiency with fast and practical machines. It is also an important feature to make delicious and high quality boreks with these fast, practical and easy functioning machines. By setting the values on the led screens of the pastry machines, the you can easily control the operation.

Capacity of Burek Machine

Separate machines are produced for pastries prepared in different forms such as water borek (”su böreği”), cigarette borek and arm borek. Not only the filling of the boreks varies, but at the same time, the thinness and thickness of the phyllo also vary according to the desired shape. While water borek is made by arranging thinly opened phyllos on top of each other, cigarette borek is made by wrapping a single phyllo sheet in a round shape. The fact that each of them has a different way of making requires different machines. There are different borek machines that provide fast and high capacity production with a single workforce. For example, the borek machine used for making water borek produces 300-350 kilograms per hour, while cigarette borek machines produce up to 100 kilograms per hour. While high product yield increases productivity, borek machines made of durable and robust parts have a long service life. Borek machines made of stainless steel can be easily used in the production facilities of enterprises as they are of different sizes.

Features of Borek Machines

It is possible to produce delicious boreks with borek machines produced for mass production of the traditional tasty boreks. Considering the speed and efficiency it provides, delicious products like handmade borek can be prepared. It has the chamber for easy placement of the desired filling. Whether it is cheese, potato or meat filling, a feast of taste emerges by the combination of delicious fillings and phyllo sheets of equal thickness. There are also many advantages that borek machines provide to businesses and companies. Some of these advantages are as follows:- With the settings on the screen of the borek machines, the amount of production, the thickness of the phyllo dough and the size of some types of boreks can be selected. This convenience provides many benefits in many aspects during the production phase.

- Borek machines are easy to use. Even if it is used for the first time by many people, it can be learnt quickly and easily.

- Cleaning of the machines as well as their production quality is a very important detail. In order for the quality of production not to decrease and the service life of the machine to continue for a long time, attention should be paid to cleaning as well as routine maintenance. While protecting it from possible problems with the safety measures taken during cleaning, it has parts that can be cleaned quickly, which ensures that the operation is not interrupted. Paying attention to the cleaning of the filling compartment, especially because of different fillings, is of great importance for the taste and quality of the boreks.

- Since the weight and size of the borek machines are large, it will be much more convenient to produce in large areas. Since it does not require much manpower, it can be easily operated by a single person. It can perform an efficient operation by keeping the production process under observation.

How Do the Borek Machines Operate?

We have already mentioned that the operation of borek machines differs for each type of borek. This is because the boreks have different fillings and shapes. For example, in the arm borek machine, there is a cutting assembly that helps to divide the phyllo orolled out in the required thickness into two equal parts from the middle. With the help of this assembly, the desired filling is placed on the phyllo which is divided into equal pieces and turned upside down at equal intervals. The assembly on both sides, which are necessary for rotating the phyllo in round form, are important for achieving the desired borek form. With Mateks Borek Machines, we aim to create a serial, economical and easy production process and to bring this technology to our users. In the borek machine models, the trays can be moved thanks to easy and fast moving scrapers on the changeable belt assembly. The parts in contact with the dough are compatible with food components, and the machine operates silently. One of the most important advantages of borek machines is that they do not have any corners. These features ensure both easy cleaning and prevention of blade jams, while at the same time preventing dust accumulation and performing a hygienic production. You can increase the production speed and quality of your business with borek machines with flouring, cutting, dough wrapping and many other units in different models and sizes. While creating the desired setting thanks to the touch screen, it also offers the opportunity to produce more per hour depending on the model.Product Categories

- Baklava Machines (3)

- Borek / Burek / Patty Machines (3)

- Horizontal Mixers (1)

- Kebbah / Kibbeh / Icli Kofte / Stuffed Meatball (1)

- Lavash Lines (1)

- Manti Ravioli Dumpling Machines (7)

- Noodle Machines (1)

- Pasteurization Machines (1)

- Phyllo Line / Yufka Line Machines (1)

- Pizza Dough / Pizza Base Machines (1)

- Sambusa Dough Machines (1)

- Shredder Machines (1)

- Thick Dough Machines (1)

- Triangular Phyllo Cutting Machines (1)

- Turkish Delight Machines (1)